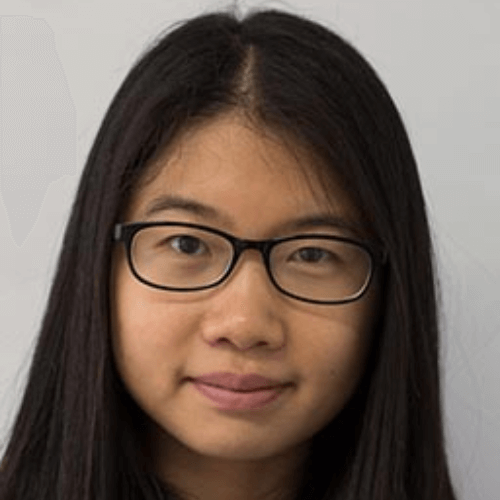

For our July Spotlight Series blog, we had a chat with Hub Member Helen Liang, CTO at LabCycle. Before LabCycle, Helen was a research scientist with a background in microbiology, biotechnology and sustainable chemical technologies. She had witnessed first-hand the problem of laboratory plastic waste in the research and healthcare sectors across different continents. Determined to solve this, she co-founded LabCycle alongside her PhD as a Marie Curie FIRE Fellow at Institute of Sustainability at the University of Bath.

In your own words what is LabCycle?

Disposable plastics have become ubiquitous in research and healthcare, especially for consumables (eg syringes, test tubes) that require sterility. Without a specialised recycling service, an enormous amount of laboratory and clinical plastic waste is currently sent to landfill or incinerated. This linear economy has imposed environmental burdens, and the value of these exceptionally high-grade plastics is lost from the supply chain.

LabCycle aims to create a solution to recycle single-use plastics from laboratories for the manufacturing of lab/medical -grade consumables, pioneering a circular economy approach in the research and healthcare sectors.

Engineering is all about solving problems. What problem is your innovation solving and what makes it ground-breaking?

During my research career, I was shocked by the amount of single-use plastic consumables (eg tubes, petri dishes, well-plates and pipette tips) that I had to go through per day. Researchers around me have been constantly talking about how bad they felt about the plastic waste generated in their work life. Ironically, a lot of their research topics are around sustainability! Even worse, none of this waste can be recycled due to concerns about health and safety – but what if they are decontaminated? What if they are no longer hazardous? What if they are even safer than stinky and mouldy household waste?

Later on, we realised the bottleneck is the lack of know-how and scalable technologies, and that’s why we developed an automated decontamination system which directly addresses this challenge. The innovation enables the safe recycling of contaminated plastic waste, laying the foundation for a circular supply chain of scientific plastics.

What was the moment that made you think “I can turn this into a commercial opportunity”?

Having been a part of the growing community that advocates for sustainable research and a Greener NHS, I realised there’s a huge demand for single-use plastic recycling, as well as more sustainable products (eg higher recycled content) in the research and healthcare sectors. Turning this into a commercial opportunity has granted us more freedom and resources to make this come true.

Wading into unknown territory can be unsettling – what were you most excited by and what was most challenging for you when starting out?

I have always been excited and motivated by the fact that I can use my knowledge and skills to create something game-changing and meaningful. Prototyping or piloting was equally exciting and challenging – the uncertainty of problem-shooting can be daunting, but I always remember the joy of seeing the final outcomes.

Can you share a time when failure mattered in your business journey?

When we first tested the recycled polymers, the quality of the samples wasn’t great. We were quite worried because this could have meant that our circular economy approach was not feasible. Luckily, upon further investigation, we realised that was because the processing temperature used by our subcontractor was way too high, causing polymer degradation. Looking back, this was more like a little bump on our journey that taught us a valuable lesson.

What has been the most surprising aspect about your entrepreneurial journey?

I have always felt lucky and thankful for the help and support offered by people from different communities and backgrounds - my entrepreneurial journey is never lonely.

What impact has the Enterprise Fellowships programme had on your business so far? What are the most valuable lessons you’ve learnt?

The trainings on pitching, presentation and investment basics equipped us for our pre-seed investment round. We are grateful for the help from our one-to-one development coach which leads to the success of an Innovate UK grant. The connections with a group of like-minded entrepreneurs are also very valuable to me.

And finally, have you got any tips for potential applicants?

Having great technology is important, but what’s more important is to make sure you have a great team and to create a great value proposition. Make sure the innovation is going to address the problem fundamentally, instead of being something that is just “nice to have”.

Quick fire

Who is your role model? My grandfather – from hospital director to medical entrepreneur, a philanthropist that influenced many people throughout his life.

Tell us a random fact not many people know about you. I never strictly follow a recipe when I cook (even the first time).

What’s your guilty pleasure? I probably make and consume too much ice cream.

When I was a child, I wanted to be… Either a scientist or a business woman (can’t remember which one came first).

I am currently binging [tv show] on Netflix/Prime… I don’t often watch TV shows. Audio books and movies are my preferred options.

Best piece of advice you’ve ever received? Stay focused.

Conversely, what has been the worst piece of advice? It's not about what you know it's about who you know (“what you know” really matters!).

I don’t understand why… People don’t like trying new things

If you were an investor, which Hub Member would you invest in? Algreen Ltd

Is there something you know now that you wish someone had told you when you started?

Sometimes it’s necessary to be assertive – just do it politely.

If you had to start all over again, would you do anything differently? If so, what?

Yes, but no one has a crystal ball. We can only go for the best option at the time, and learn how to create better options in the future.

The Royal Academy of Engineering Enterprise Hub supports the UK’s brightest technology and engineering entrepreneurs to realise their potential.

We run four programmes for entrepreneurial engineers at different career stages. Each one offers equity-free funding, an extended programme of mentorship and coaching, and a lifetime of support through connection to an exceptional community of engineers and innovators.

The Enterprise Hub focuses on supporting individuals and fostering their potential in the long term, taking nothing in return. This sets us apart from the usual ‘accelerator’ model. The Enterprise Hub’s programmes last between 6 and 12 months, and all programmes give entrepreneurs lifelong access to an unrivalled community of mentors and alumni.

Our goal is to encourage creativity and innovation in engineering for the benefit of all. By fostering lasting, exceptional connections between talent and expertise, we aim to create a virtuous cycle of innovation that can deliver on this ambition.

The Enterprise Hub was formally launched in April 2013. Since then, we have supported over 350 researchers, recent graduates and SME leaders to start up and scale up businesses that can give practical application to their inventions. We’ve awarded over £11 million in grant funding, and our Hub Members have gone on to raise over £1.3 billion in additional funding.