Novosound Ltd manufactures advanced ultrasound sensors for non-destructive testing (NDT) of corrosion across industries including energy, aerospace and power generation. Traditional testing can be time consuming, owing to the need to shut down the supporting infrastructure, and costly because of the number of people needed to carry out the job. In addition, established technology has been hampered by poor signal conduction with sensors often unable to fit curved surfaces or work at high temperatures.

Novosound has found a way around existing problems by replacing conventional sensor materials with flexible piezoelectric thin-film technology. The company says that this patented technology has helped develop its primary NDT products: the Kelpie and Belenus. Designed to simplify complex inspections, the Kelpie’s flexible and low profile design facilitates the inspection of difficult geometries and hard-to-reach areas. The Belenus is the world’s first flexible NDT ultrasound ‘fit and forget’ tool that can measure corrosion at up to 400° C, with regular data capture and remote monitoring via cloud computing.

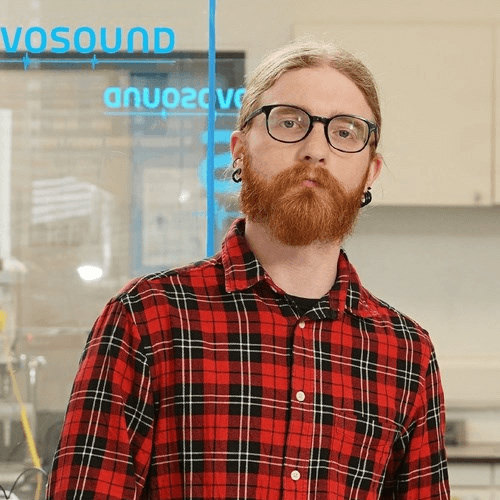

Daniel Irving is Novosound ‘s Executive Product Development Manager. Daniel worked his way up from being the company’s first full-time engineer to leading the technical and engineering team. He joined the Scale Up Accelerator programme in 2021 and will use it “to formalise my knowledge and skills in leadership and management”. He believes “the training and coaching will cement that skillset and the networking will guide and support me through the challenges of growing a technical company”.

Investors have shown confidence in Novosound’s technology for corrosion and erosion monitoring by supplying it with over £3 million in Series A funding. In the coming years, the company intends to move away from one-off sales to recurring revenues through data and licensing. It is also looking to diversify by developing biomedical technology in addition to its successful industrial products.

Associated Programme