Inductosense Ltd, a spinout from the University of Bristol, designs and manufactures ultrasonic sensor technology. The company’s patented wireless and non-destructive (WAND) system is proving particularly effective in monitoring internal corrosion and erosion in pipework and vessels. The non-destructive testing technology has been taken up by the petrochemical and oil and gas industries, and others.

WAND consists of thin, wireless sensors that can provide fast, repeatable detection of cracks, defects, corrosion and erosion in structures and products. Battery-free, the sensors can be permanently embedded underneath coatings and insulation for the lifecycle of a product. They are passive, with the power and signal provided remotely by non-contact inductive coupling with a handheld or remote data collector.

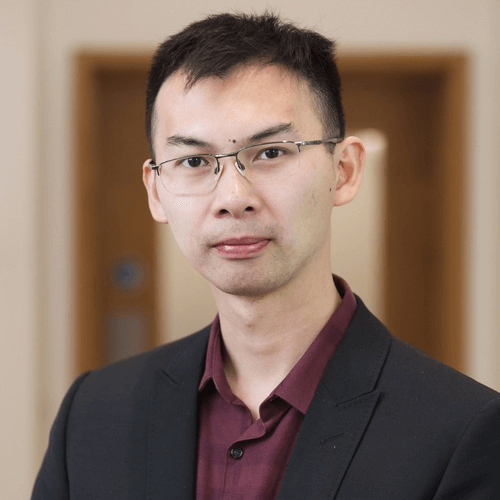

Dr Cheng-Huan Zhong is the co-founder and CTO at Inductosense. Cheng-Huan developed the breakthrough technology and is now looking to help the business scale up. He joined the Shott Scale Up Accelerator in 2022 and says, “I would like to develop my decision-making, communication and influencing skills to help the company make the right decisions. The accelerator would also enable me to identify and grow the potential of employees, to help them progress and further develop their talents.”

Inductosense’s cost-effective WAND sensors are proving popular because they can be deployed in large numbers, enabling a more streamlined approach to corrosion monitoring. With the launch of its remote data collection device, the company is looking to significantly increase its revenue and move into adjacent markets such as mining and renewables. Inductosense already supplies major operators in 15 countries. With new products and automation being introduced into the production process, the company will be looking to increase this number further.

Associated Programme